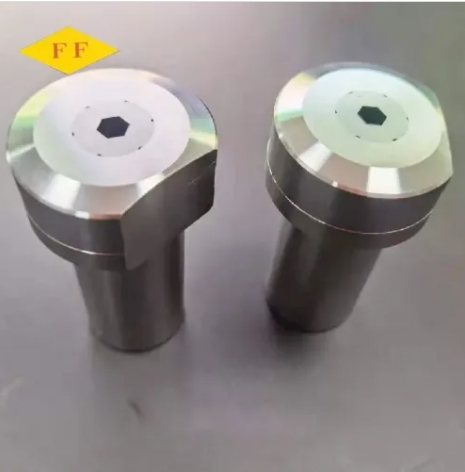

All our Segmented Hex Dies are made by high-precision fixture with imported tungsten steel and advanced hot pressing process. It has improved the defect of swelling on the side and emerging the six strips under normal use.

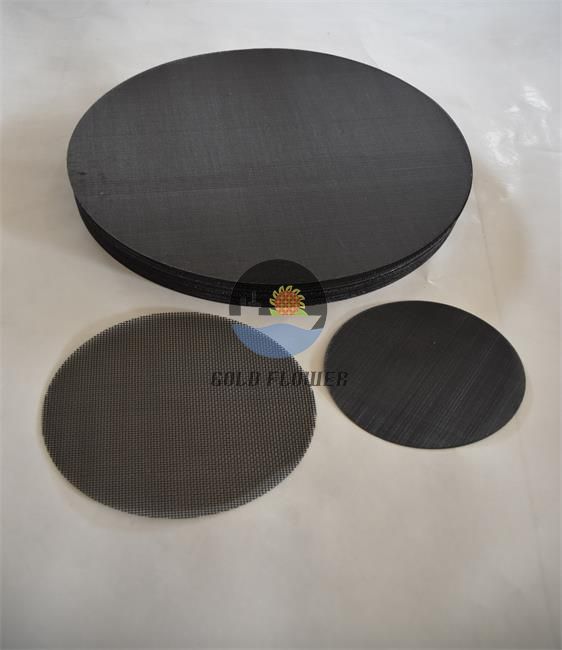

the tungsten carbide dies we supply for customer including: Straight hole insert mold Extrusion hole insert mold Cutter knife mold Wire drawing mold Tube drawing mold Multiple-position mold Miscellaneous molds for screw machine The details of die case size, wire diameter, length or screw size when you inquire or order tungsten carbide inserted for making different type/shape of screws. It is highly suggested that you send the drawings or screw samples for our reference

our advantages 1. High quality 2. Reasonable price 3. On time delivery 4. Good After-sale service 5. Strict quality control 6. All the mold are automotic. We will offer you 1. In-time response on letters, telephone calls or fax 2. In-time supply the quotation and mold designs 3. In-time communication on the technical points 4. In-time sending pictures for the mold machining progress and mold finishing schedule 5. In-time mold test and sample delivery 6. In-time mold delivery.

What are types of thread cutting dies?

Hand threading dies are generally of two types. ROUND dies are designed to fit in a T-handle while HEX DIE NUTS can be used with regular hand tools. (Wrenches and sockets.) Round dies are usually the choice for cutting new threads whereas hex die nuts are commonly used as a chaser to repair existing threads

What is the purpose of adding lubricant when cutting threads?

Applying the proper lubricants in tapping operations can result in longer tap life, increased production, better workpiece size control, smoother and more accurate threads, less resharpening, and more efficient chip removal. Generally, for best tap performance, straight cutting oil should be used.

More information please click here.

No information

Product:

Shipping To

Quantity

Contact Person

Valid for

Company/Institute

Notes

Successful

Successful submission of information.