Tungsten steel thimble - made of tungsten steel, ground by precision equipment, with high hardness, strength, wear resistance, and excellent corrosion resistance. At present, it is suitable for plastic moulds, lathes and grinders, and for tungsten steel electrode rod in photoelectric industry

Physical properties of

1 g/cm3 density: 14.5

(2) the hardness of HRA: 91.5

(3) Co content: 10%

④ Grain size :1.0um

⑤ Bending strength N/mm2:≥2800

⑥ Thermal expansion coefficient 10-6/0c :4.9

Modulus of elasticity GPa:525

The production process

Ingredients (according to the requirements of applicable selection of tungsten carbide powder + cobalt powder) to the mix - crushing - drying, sieving after forming agent and dry again to sieving mixture system, the mixed system, pressing - molding - Germany import vacuum suit low sintering sintering furnace - after sintered blank - test (nondestructive ultrasonic flaw detection) - blank dimensions accuracy test - cutting molding to coarse grinding, fine grinding → polishing → inspection → packaging → storage

features

(1) Due to the addition of tantalum carbide TaC with excellent wear resistance and TiC with excellent heat resistance and wear resistance, the alloy has high wear resistance, and its service life is more than 3 times that of SKH51 high-speed steel and 65Mn steel.

② The size is accurate, the processing accuracy is high, the polishing finish reaches Ra≥0.012 mirror effect.

③ Tungsten steel thimble has excellent corrosion resistance and no rust, can work in acid, alkaline environment, can greatly reduce the maintenance cost and maintenance time

application

① Tungsten steel thimble is suitable for making plastic mold industry flat thimble, round thimble, supporting needle, standard thimble, non-standard thimble and other mold accessories.

② Tungsten steel thimble is suitable for positioning wear-resisting parts on lathes and grinds.

③ Tungsten steel thimble is suitable for making tungsten steel electrode rod in photoelectric industry

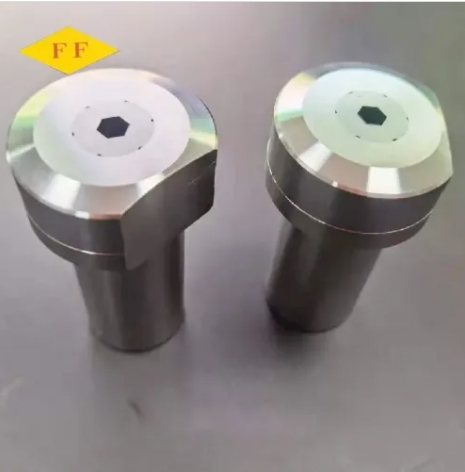

We manufactures steel and carbide dies in a variety of head styles and configurations.Including:

Straight Hole

Extrusion

Segmented Hexagon Carbide Die

Header Point

Washer Faces

Countersunk Head

Trapped Extrusion.

Associated tools are aslo available ,such as Cutoff Knives,Cutter Inserts,Extrusion Pins,Knockout Pins

Fingers,Press Fit Punch Casings,Hexagon Head Pins

Please specify the details as follow when you inquire,

1.Header machine Die case size

2.Screw wire diameter

3.Screw size & length

No information

Product:

Shipping To

Quantity

Contact Person

Valid for

Company/Institute

Notes

Successful

Successful submission of information.